Exploring the Versatility of Nickel Alloy Flanges and Pipe Fittings

July 15, 2023 - 0 COMMENTS

Introduction:

Nickel alloys are renowned for their exceptional resistance to corrosion, high-temperature applications, and excellent mechanical properties. These attributes make them highly suitable for a wide range of industries, including chemical processing, oil and gas, power generation, and more. In this blog, we will delve into the world of nickel alloy flanges and pipe fittings, exploring their benefits, applications, and key considerations for selecting the right materials.

- The Advantages of Nickel Alloy Flanges: Nickel alloy flanges offer several advantages that make them a preferred choice in demanding industrial environments. Here are some key benefits:

This resistance allows them to maintain structural integrity and durability even in highly corrosive conditions.

- High-Temperature Strength: Nickel alloy flanges retain their mechanical properties at elevated temperatures, making them suitable for applications that involve high heat and thermal cycling. They offer excellent creep and stress-rupture resistance, ensuring long-term performance under extreme conditions.

- Versatility: Nickel alloys are available in a wide range of grades, each tailored to specific applications. This versatility allows for compatibility with various process fluids, chemicals, and gases, making them suitable for diverse industrial sectors.

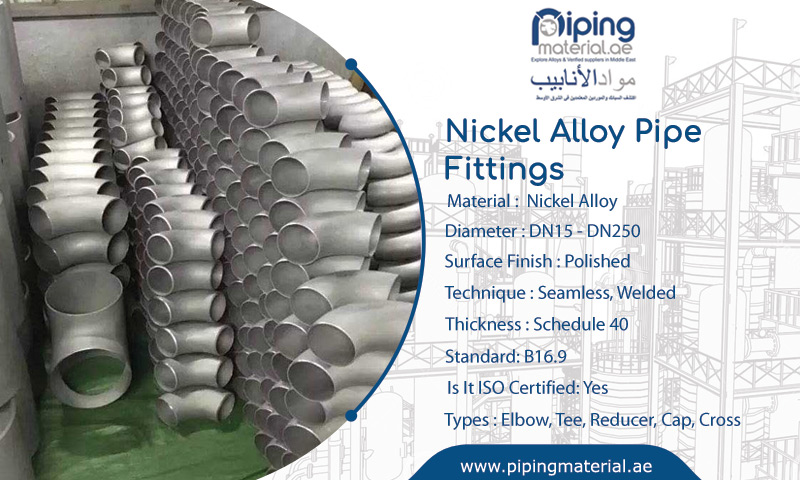

- Common Nickel Alloy Pipe Fittings: Nickel alloy pipe fittings play a crucial role in ensuring reliable and leak-free connections in piping systems. Let’s explore some commonly used nickel alloy pipe fittings:

- Nickel Alloy Elbows: Elbows are used to change the direction of a piping system. Nickel alloy elbows are designed to withstand high temperatures and corrosive environments while maintaining the flow characteristics of the system.

- Nickel Alloy Tees: Tees provide a branch connection in a piping system. Nickel alloy tees offer excellent corrosion resistance and are widely used in industries where process fluids or gases need to be diverted or distributed.

- Nickel Alloy Reducers: Reducers are used to connect pipes of different diameters, allowing for smooth transition and flow control. Nickel alloy reducers ensure compatibility, strength, and resistance to corrosion.

- Nickel Alloy Couplings: Couplings are used to join two pipes together. Nickel alloy couplings provide secure and leak-free connections, even in high-pressure and high-temperature applications.

- Applications of Nickel Alloy Flanges and Pipe Fittings: Nickel alloy flanges and pipe fittings find extensive application across various industries. Here are some notable examples:

- Chemical Processing: Nickel alloys are widely used in chemical processing plants where resistance to corrosion from aggressive chemicals is crucial. Flanges and fittings made from nickel alloys ensure the integrity of the piping systems, even when handling corrosive fluids.

- Oil and Gas Industry: The oil and gas industry often encounters demanding conditions such as high temperatures, pressures, and corrosive environments. Nickel alloy flanges and fittings play a vital role in ensuring reliable performance, integrity, and safety of the pipelines, valves, and equipment.

- Power Generation: Nickel alloy flanges and pipe fittings are extensively used in power plants, particularly in high-temperature and high-pressure applications. They help maintain efficient operations and prevent leakage, ensuring the reliability and safety of power generation systems.

- Considerations for Selecting Nickel Alloy Flanges and Pipe Fittings: When selecting nickel alloy flanges and pipe fittings, several factors should be considered:

- Corrosion Resistance: Evaluate the compatibility of the nickel alloy with the process fluid, gas, or chemical it will come into contact with. Ensure that the selected alloy offers adequate resistance to corrosion in the specific operating conditions.

- Temperature and Pressure Ratings: Determine the temperature and pressure requirements of the application and choose flanges and fittings that can withstand those conditions without compromising their performance.

- Material Grade Selection: Different nickel alloys have varying mechanical properties and resistance to corrosion. Consider the specific requirements of your application and select the appropriate material grade to ensure optimal performance and longevity.

- Compliance with Standards: Ensure that the selected nickel alloy flanges and pipe fittings comply with industry standards and regulations to guarantee their quality, reliability, and safety.

Conclusion:

Nickel alloy flanges and pipe fittings offer a wide array of advantages, making them indispensable components in many industrial sectors. Their exceptional resistance to corrosion, high-temperature strength, and versatility enable them to withstand demanding conditions and ensure the integrity of piping systems. By carefully considering the application requirements and selecting the right nickel alloy grades, industries can benefit from the reliability, durability, and longevity that these components provide.